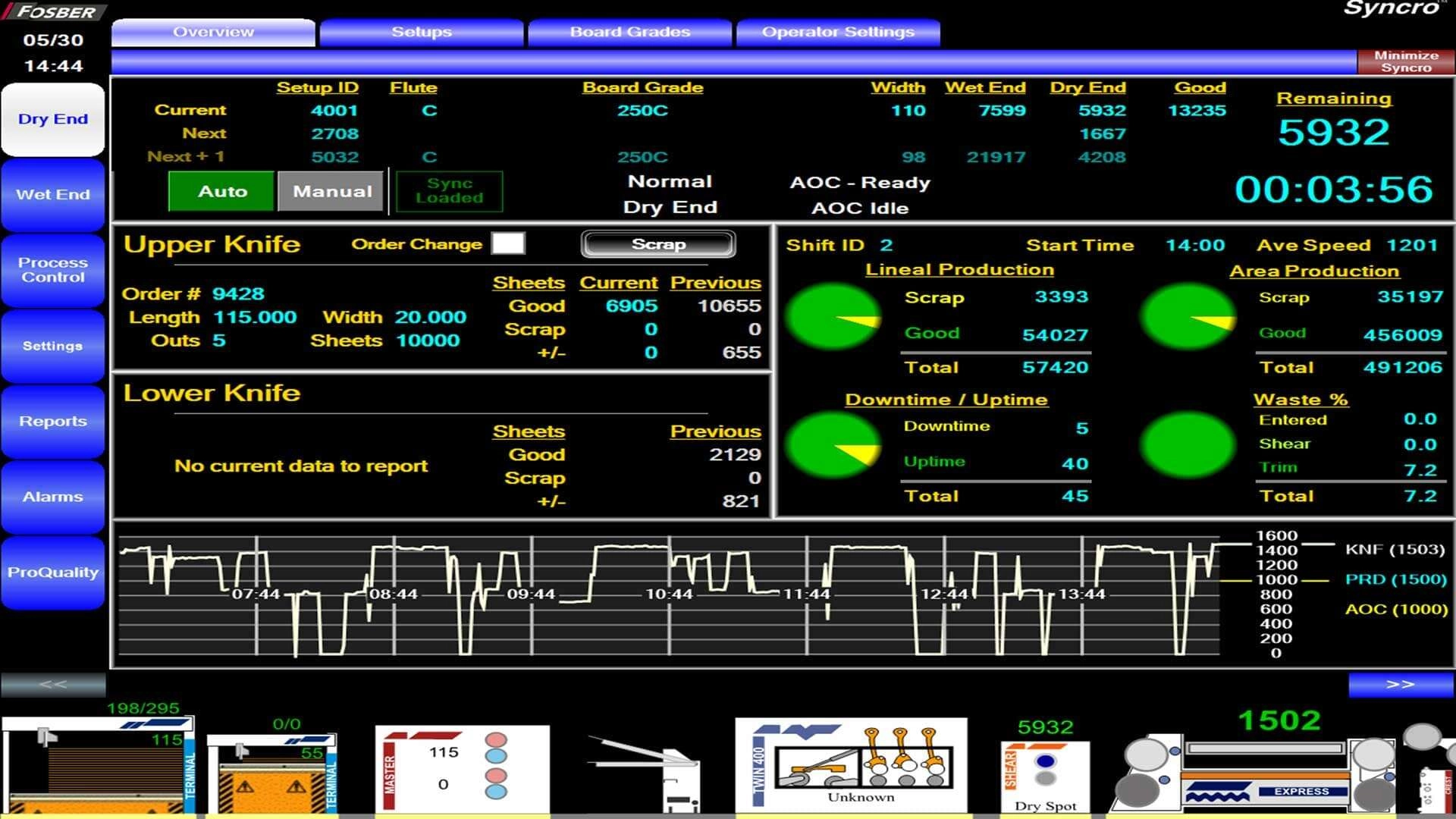

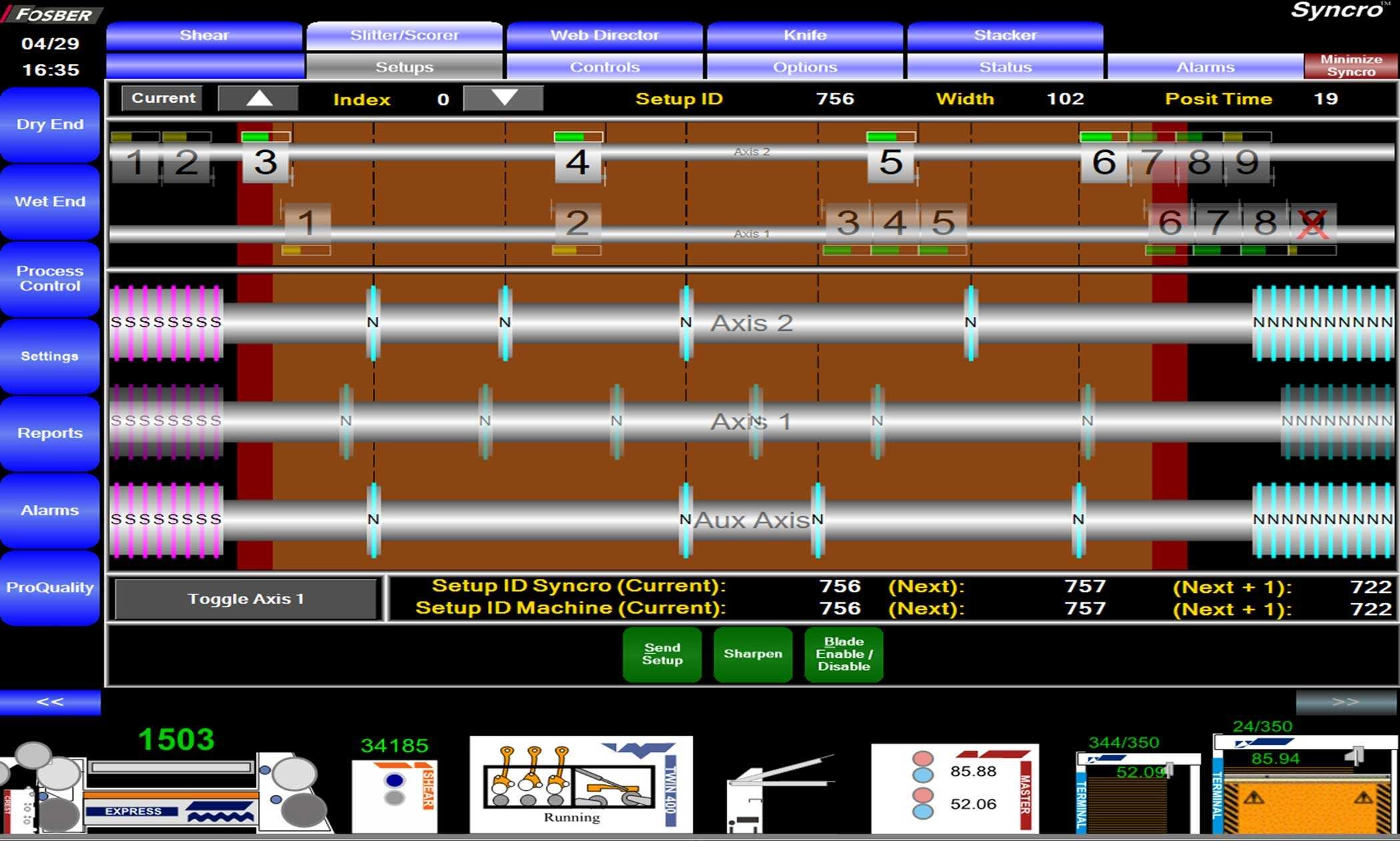

Syncro

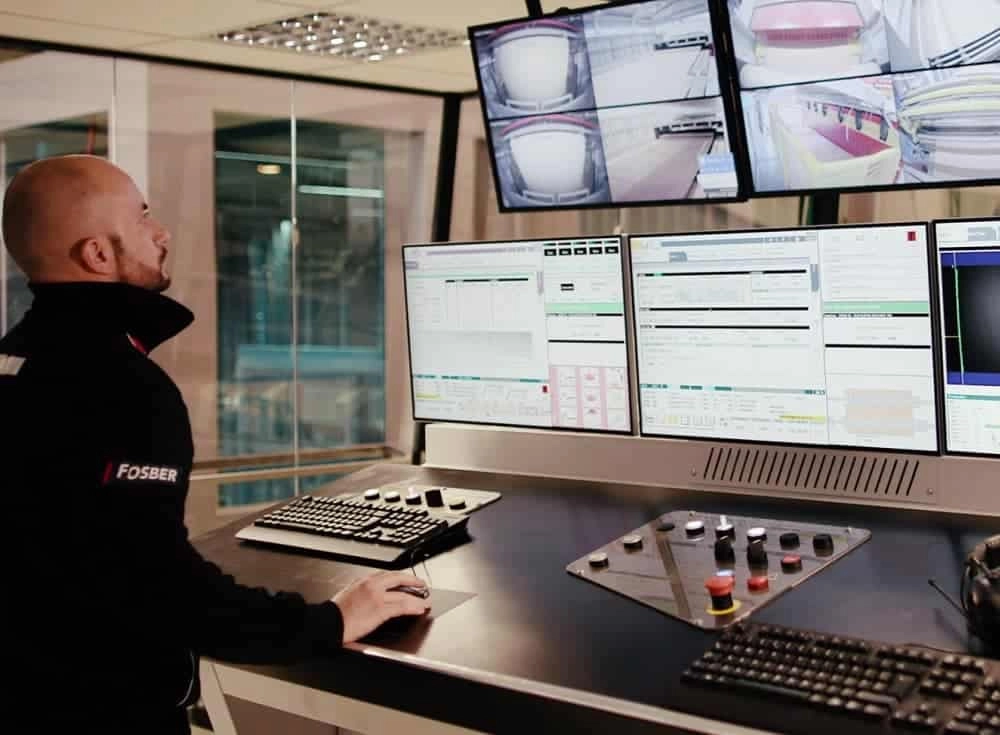

Syncro is Fosber’s computer-based corrugator control system. Syncro utilizes intuitive touch screens to display information utilizing machine signals and production information of a complete corrugator. The Syncro can provide control, monitoring, information display, data entry, diagnostics, and centralized operation for a complete corrugator or individually on the DryEnd or WetEnd. The system is modular, flexible and can be configured to individual plant requirements.

WetEnd Controls

- Synchronized Splice Controls

- Bridge Control for the Singlefacers

- Interfaces with the WetEnd Machines and DryEnd Controller

- Paper Break Detection

- Roll Label Printing for Butt Rolls

- Roll Stock System Interface w/Bar Code Reading Capabilities

- Line Speed Reference Generation

DryEnd Controls

- DryEnd Order Change Control

- Interfaces w/the DryEnd Machines/WetEnd Controller

- Interface to the Office Scheduling System

- Production Reporting

- Overhead & Machine Display Management

- Line Speed Reference Generation

Process Controls

- Automatically Monitors & Controls Machine Settings

- Default Target Process Settings Using Paper Grades Categories

- Customizable Settings for Specialized Board Grades

- Device Monitoring and Control

- Wrap Arms for SingleFacer, Standalone Pre-Heaters, & DoubleFacer

- Glue Gaps for SingleFacer & Glue Machine

- Steam Shower for SingleFace

- Paper Tensions at Splicers & Bridge Brake

- DoubleFacer Steam Pressure & Shoe Pressure

- Closed-Loop Warp Control System

- Up to 3 sensors across the web

- Fully Integrated Corrugator Control System

- WetEnd Control

- DryEnd Control

- Process Control

- Intuitive Screen Controls Allow for Easy Personnel Training

- 24 Hour Online Support

- System is Designed to be Expandable for Future Enhancements

- ProCare

- ProQuality

- RPS-RealTime Production Supervisor-Event Based DVR System

- Distributed I/O Network on Standard Ethernet

- Machine Alarm Diagnostics

- Syncro Reporting – Export Capability and Data Analysis and Historical Process Control Lookup

Gallery