Syncro is Fosber’s cutting-edge, computer-based corrugator control system, designed to provide seamless integration and optimization across various machinery configurations. This flexible system allows for comprehensive control of both Fosber and non-Fosber equipment, adapting to different corrugator configurations with ease.

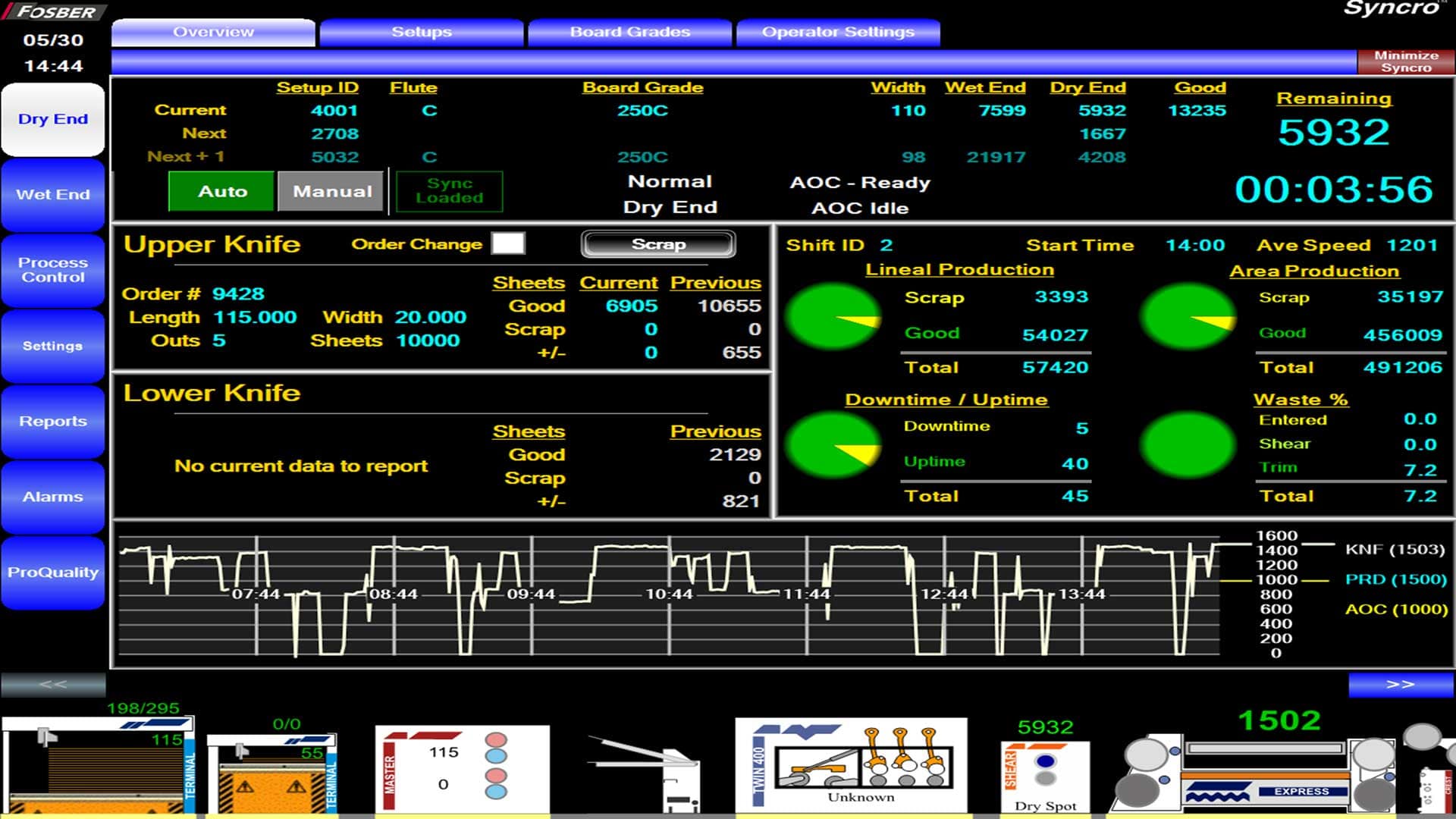

Syncro offers the capability to function as a complete corrugator controller or as a dedicated WetEnd or DryEnd controller, ensuring efficient operation tailored to specific production requirements. Its intuitive touch-screen interface provides operators with a centralized hub for monitoring, control, and diagnostics, streamlining workflows and enhancing operational efficiency.

In addition, Syncro is designed to interface seamlessly with Fosber’s suite of add-on packages, including ProCare, ProQuality, and RPS (RealTime Production Supervisor). These advanced solutions further enhance automation, quality control, and real-time production monitoring, allowing manufacturers to optimize performance, maintain product consistency, and maximize operational output.

With advanced automation and user-friendly controls, Syncro empowers manufacturers with precision, reliability, and adaptability optimizing corrugation processes for maximum productivity.

- Fully Integrated Corrugator Control System

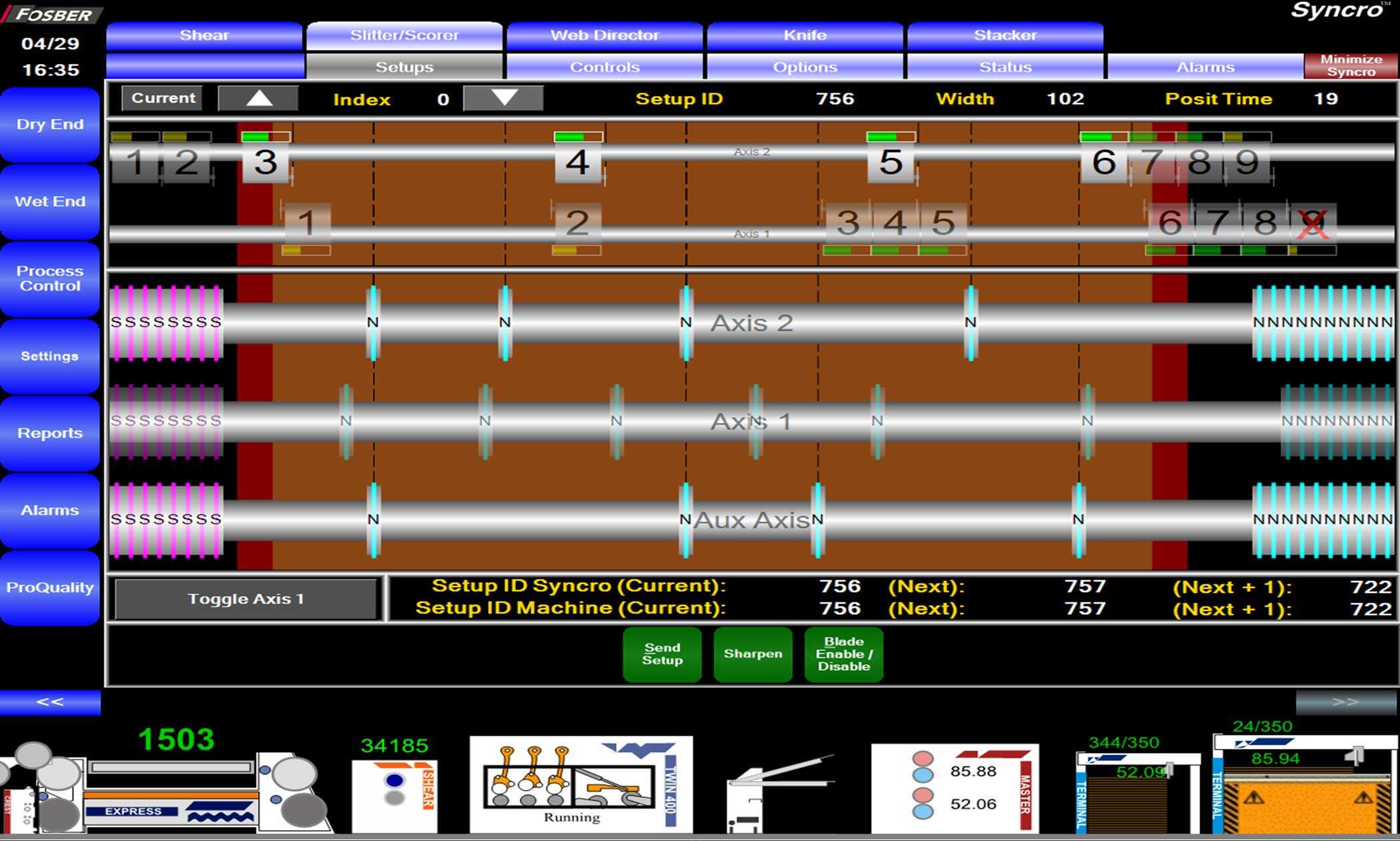

- WetEnd Control

- DryEnd Control

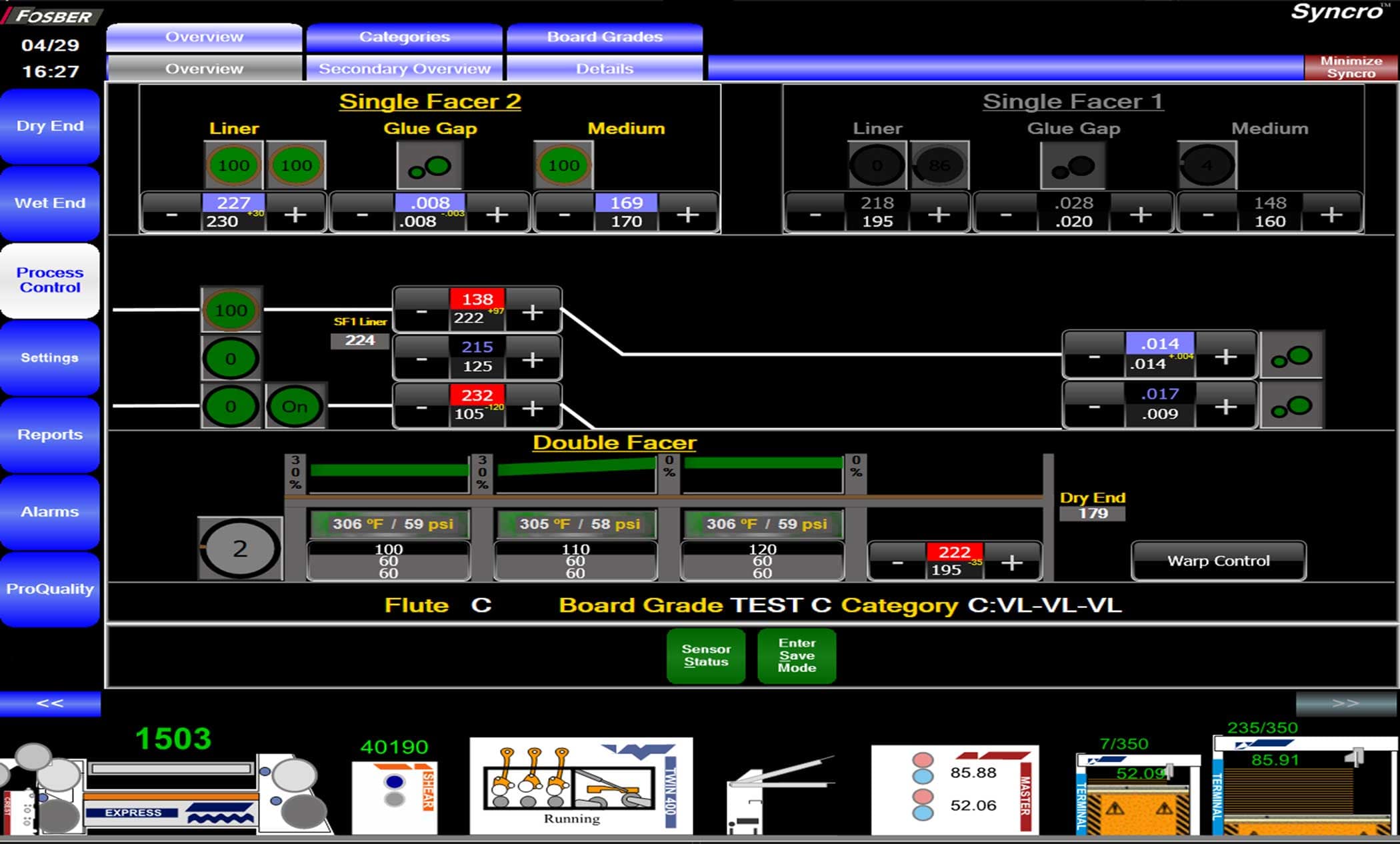

- Process Control

- Intuitive Screen Controls Allow for Easy Personnel Training

- System is Designed to be Expandable for Future Enhancements

- ProCare

- ProQuality

- RPS-RealTime Production Supervisor-Event Based DVR System

- Distributed I/O Network on Standard Ethernet

- Machine Alarm Diagnostics

- 24 Hour Online Support

WetEnd Controls

- Synchronized Splice Controls

- Bridge Control for the Singlefacers

- Interfaces with various WetEnd Machines and DryEnd Controllers

- Paper Break Detection

- Interface to Roll Stock Systems

- Line Speed Reference Generation

DryEnd Controls

- DryEnd Order Change Control (Gap/No-Gap)

- Interfaces with various DryEnd Machines and WetEnd Controllers

- Interface to Office Scheduling Systems

- Interface to Material Handling Systems

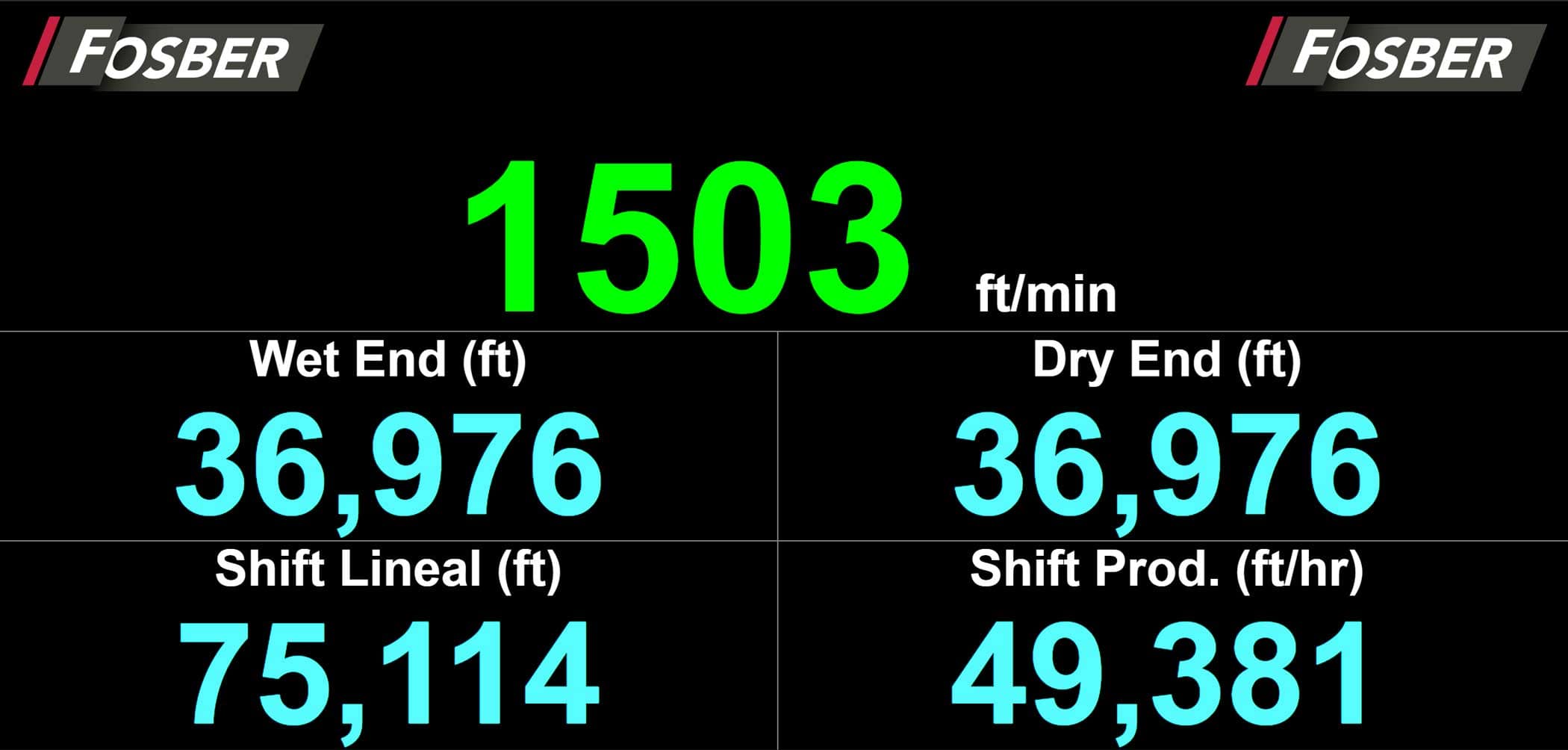

- Overhead & Machine Display Management

- Line Speed Reference Generation

Process Controls

- Automatically Monitors & Controls Machine Settings

- Default Target Process Settings Using Paper Grades Categories

- Customizable Settings for Specialized Board Grades

- Device Monitoring and Control

- Wrap Arms for SingleFacer, Standalone Pre-Heaters, & DoubleFacer

- Glue Gaps for SingleFacer & Glue Machine

- Steam Shower for SingleFace

- Paper Tensions at Splicers & Bridge Brake

- DoubleFacer Steam Pressure & Shoe Pressure

- Water Decks

- Closed-Loop Warp Control System

- Up to 3 sensors across the web

- Thermal Imaging

Reporting

-

- Auto Print/Email Reporting

- Export Capable

- Historical Data Analysis with Snapshot

- Real Time Data Analysis with RTM (RealTime Monitor)

- Process Control setpoint Lookup